GPS Heavy Equipment Monitoring Systems

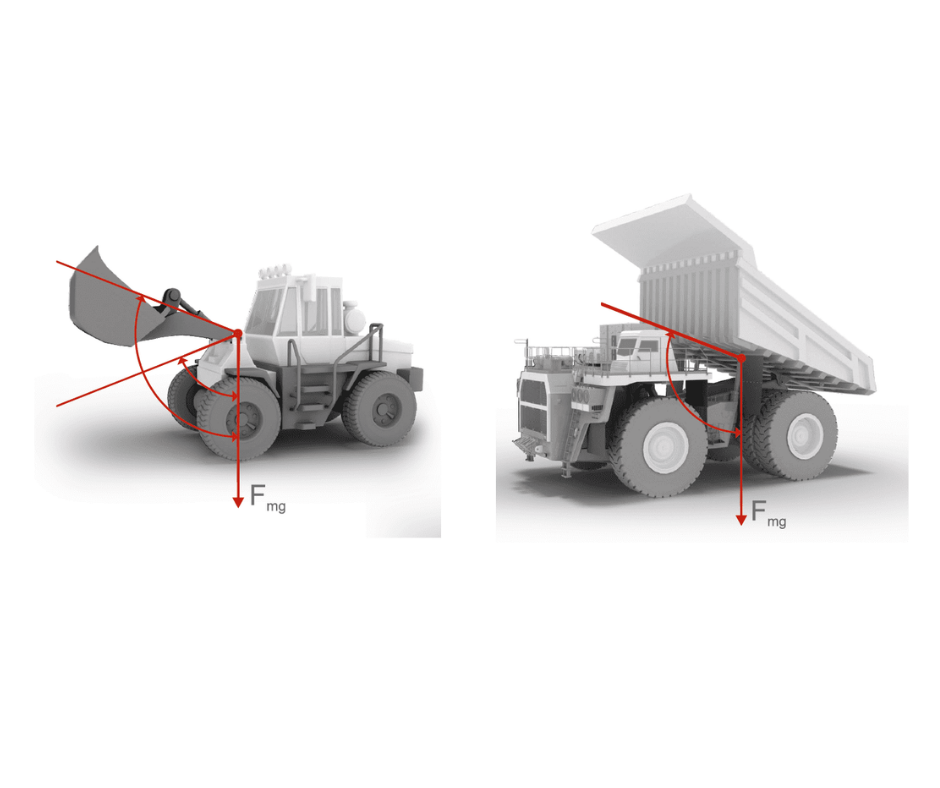

We provide the best GPS Heavy equipment monitoring systems in Sri Lanka. Our GPS systems uses mechanisms relative to the gravity vector for precise orientation monitoring. The data is transmitted over BLE low power with GPS tracking for real-time location and movement information. You can get all the information of your construction or heavy equipment, real-time to your android, apple or computer device.

Why This is The Best GPS Heavy Equipment Monitoring System in Sri Lanka

Kommnet’s heavy machinery/equipment monitoring system can correctly measure the real machine hours. So the construction vehicle operator can’t cheat by just switching on the engine. They have to actually work using the equipment. Because in our system, angle sensors transmits the measured values of 3 angles relative to the gravity vector and then sends these parameters to a GPS tracker over BLE-protocol: Angle X, Angle Y, Angle Z, Number of events and Number of chains.

In addition to measuring the tilt angles, the tracking sensor determines events and chains of events. An event is detected when angle have gone beyond the specified boundaries. A chain of events is the fulfillment of the conditions of a sequence of events separated by time intervals.

Additional features of Kommnet’s heavy equipment GPS tracking system

- Designed to use in harsh weather conditions.

- One centralized cloud-based solution.

- Easy Installation.

- Geofence Alerts.

- Ability to add extra features as your needs.

- Using BLE low power technology.

- Reduced mobile data Costs.

- Machine operational status in real time with GPS data.

- Accurately track real machine hours and idle ratio.

- Help prevent unauthorized use and theft.

- Customizable according to your needs.

- Track your machines easily using mobile app or web based software.

- Long life time due to high standard GPS tracking products.

Use cases

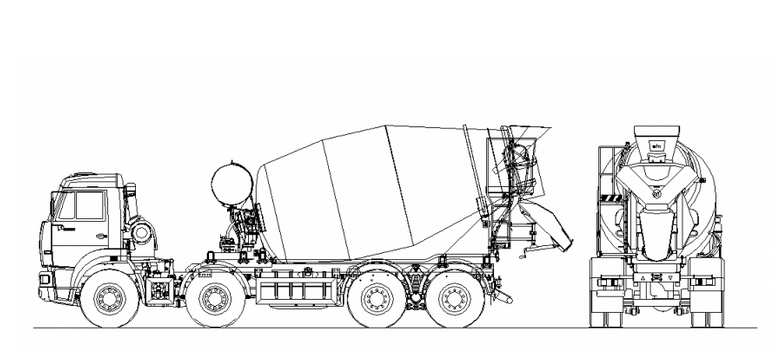

Tracking Concrete Mixers

The concrete mixer truck is outfitted with an advanced solution that uses a heavy equipment GPS tracker and an angle sensor to monitor the drum's rotation. This integration enables precise tracking of the mixer's operational time and location, to optimize performance and prevent theft.

By tracking the rotation of the drum, our GPS heavy machinery tracking solution can accurately identify when and where the mixer is being used, therefore you can pinpoint potential areas for improvement. For example, the data can be used to identify the exact location and time of any concrete theft incidents. Additionally, the tracking data can be used for analytical purposes, enabling you to make informed, data-driven decisions and improve your business processes accordingly.

- Info on when and where every loading and unloading took place.

- Total drum operation time.

- Drum rotation speed.

- A number of starts.

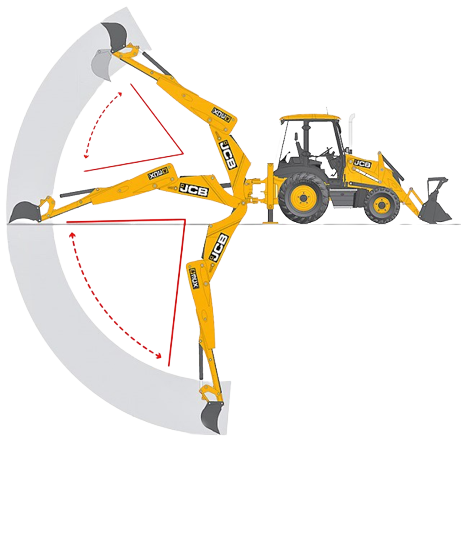

Tracking Excavators

The Wireless angle sensor is the ideal solution that can be installed on heavy machinery such as excavators. By integrating GPS technology, the angle sensor provides real-time reports on the movements of the dipper arm, including the frequency and duration of movements, as well as time spent working or idling with GPS information.

This integration provides tracking the operational status of the machine, allowing you to monitor and optimize its performance. The data provided by the solution can be used to make decisions about maintenance and repair schedules, and to assess the machine's productivity and efficiency.

- The machine is operation/not operating.

- Calculates the total time of real working hours

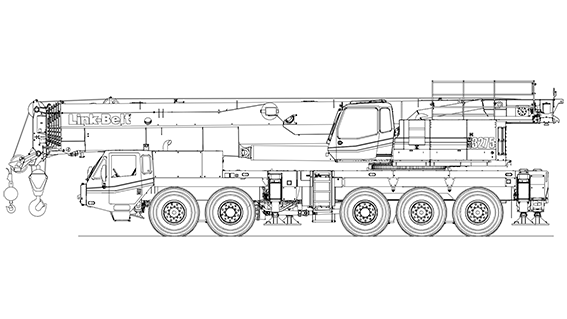

Tracking Cranes

The Wireless angle tracking sensor can be integrated with cranes by installing it on the telescopic boom. This allows for real-time reports on the frequency and duration of boom movements, along with precise GPS information.

This data is essential for monitoring crane working hours and identifying areas for improvement. With its ease of installation and advanced features, our monitoring system is a powerful tool for optimizing crane operations and enhancing your overall performance.

- The crane is operation/not operating.

- Calculates the real working hours.

You can track any type of heavy machinery using our heavy equipment tracking system. Because we have customized devices for any type of machines/ construction vehicles.

Benefits of Using a GPS Monitoring System for Your Construction Equipment

Always Know Where Your Equipment Is

Stay informed about the location of your heavy equipment, even in remote areas, ensuring better control and security

Real-Time Insights on Equipment Status

Receive instant updates on engine status, total miles traveled, unauthorized use, and the precise location of each piece of equipment for proactive management

Reduce Maintenance Costs, Increase Profits

Enable maintenance personnel to efficiently locate and service vital machinery, reducing wear and maintenance costs and ultimately increasing profits.

Minimize Downtime

Track and monitor to minimize equipment and driver downtime, ensuring a more productive and streamlined workflow

Efficient Scheduling and Routing

Always know the whereabouts of your asset, enabling better management for scheduling and routing to enhance overall operational efficiency

Convenient method to tracking. Software or Mobile App

Using a centralized heavy equipment tracking system enables you to choose different methods such as mobile apps or software to access data.